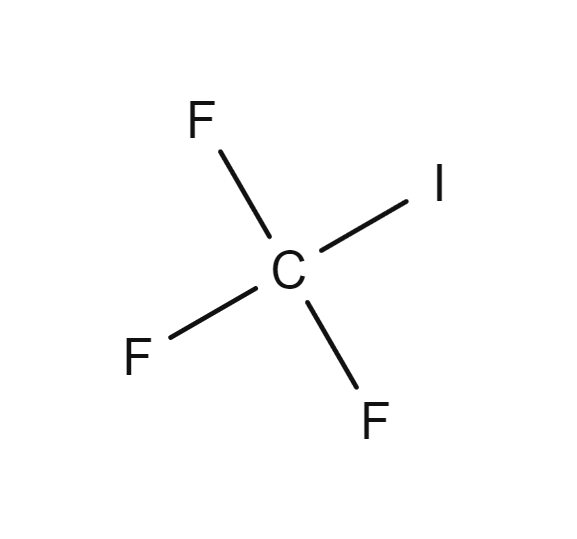

Trifluoroiodomethane

- CF3I

- CAS Number 2314-97-8

- UN1956 (gas)

Click & drag to move the 3D molecule

Liquid / Gas Volumes

Calculate the volume or mass of a quantity of gas or liquid

Liquid Phase

At boiling point at 1.013 bar

Gas Phase

In standard conditions (1.013 bar, 15°C)

Physical Properties

Molecule phase diagram showing the transition phases between solid, liquid and gas as a function of temperature and pressure

-

- Molar mass 195.910 g/mol

- Content in dry air /

-

Critical Point

- Temperature 123.29 °C

- Pressure 39.53 bar

- Density 869.57 kg/m³

-

Triple Point

- Temperature -78.00 °C

- Pressure 4.87E-2 bar

Pressure 1.013 bar

| Latent heat of fusion (at melting point) | 35.067 kJ/kg |

| Melting point | - 78 °C |

Pressure 1.013 bar

| Boiling point | - 21.85 °C |

| Latent heat of vaporization (at boiling point) | 103.962 kJ/kg |

| Liquid density (at boiling point) | 2248.9 kg/m3 |

| Compressibility factor Z | 9.6947E-1 |

| Cp/Cv ratio γ | 1.1688 |

| Gas density (at boiling point) | 9.909 kg/m3 |

| Gas density | 9.0159 kg/m3 |

| Gas/(liquid at boiling point) equivalent | 254.81 vol/vol |

| Heat capacity Cp | 3.4186E-1 kJ/(kg.K) |

| Heat capacity Cv | 2.925E-1 kJ/(kg.K) |

| Specific gravity | 6.9 |

| Specific volume | 1.109E-1 m3/kg |

| Thermal conductivity | 5.978 mW/(m.K) |

| Viscosity | 1.3003E-4 Po |

| Compressibility factor Z | 9.7475E-1 |

| Cp/Cv ratio γ | 1.1603 |

| Gas density | 8.5003 kg/m3 |

| Gas/(liquid at boiling point) equivalent | 270.27 vol/vol |

| Heat capacity Cp | 3.4725E-1 kJ/(kg.K) |

| Heat capacity Cv | 2.9928E-1 kJ/(kg.K) |

| Specific gravity | 6.9 |

| Specific volume | 1.177E-1 m3/kg |

| Thermal conductivity | 6.459 mW/(m.K) |

| Viscosity | 1.377E-4 Po |

| Compressibility factor Z | 9.7759E-1 |

| Cp/Cv ratio γ | 1.1557 |

| Gas density | 8.1913 kg/m3 |

| Gas/(liquid at boiling point) equivalent | 280.46 vol/vol |

| Heat capacity Cp | 3.5084E-1 kJ/(kg.K) |

| Heat capacity Cv | 3.0357E-1 kJ/(kg.K) |

| Specific gravity | 6.9 |

| Specific volume | 1.221E-1 m3/kg |

| Thermal conductivity | 6.779 mW/(m.K) |

| Viscosity | 1.4276E-4 Po |

Applications

Examples of uses of this molecule in Industry and Healthcare

Aeronautics

Trifluoroiodomethane would be used as a gaseous fire suppression flooding agent for in-flight aircraft and electronic equipment fires.

Safety & Compatibility

GHS04

Gas under pressure

GHS06

Acute Toxicity

Metals

| Aluminium | No data |

| Brass | No data |

| Monel | No data |

| Copper | No data |

| Ferritic Steel | No data |

| Stainless steel | No data |

| Zinc | No data |

| Titanium | No data |

Plastics

| Polytetrafluoroethylene | No data |

| Polychlorotrifluoroethylene | No data |

| Polyvinylidene fluoride | No data |

| Polyvinyl chloride | No data |

| Ethylene tetrafluoroethylene | No data |

| Polycarbonate | No data |

| Polyamide | No data |

| Polypropylene | No data |

Elastomers

| Butyl (isobutene- isoprene) rubber | No data |

| Nitrile rubber | No data |

| Chloroprene | No data |

| Chlorofluorocarbons | No data |

| Silicone | No data |

| Perfluoroelastomers | No data |

| Fluoroelastomers | No data |

| Neoprene | No data |

| Polyurethane | No data |

| Ethylene-Propylene | No data |

Lubricants

| Hydrocarbon based lubricant | No data |

| Fluorocarbon based lubricant | No data |

Materials compatibility

Learn More

More information

Due to their ozone-depleting effect, the production of refrigerants is continuously decreasing, based on Montreal protocol requirements. Their use is controlled and they are progressively being replaced.