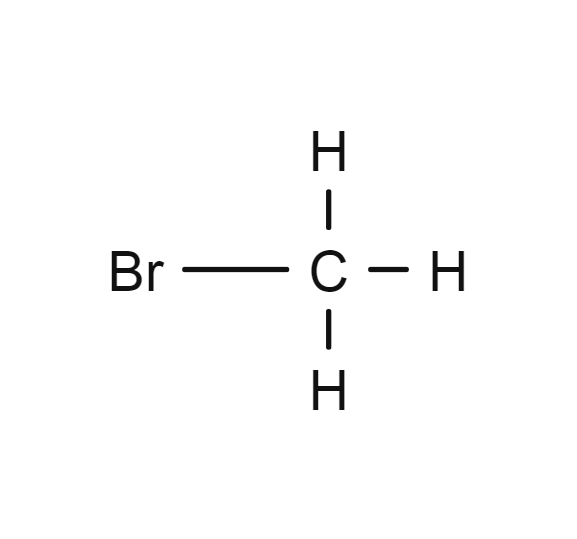

Methyl bromide

- CH3Br

- CAS Number 74-83-9

- UN1062 (gas)

Click & drag to move the 3D molecule

Liquid / Gas Volumes

Calculate the volume or mass of a quantity of gas or liquid

Liquid Phase

At boiling point at 1.013 bar

Gas Phase

In standard conditions (1.013 bar, 15°C)

Physical Properties

Molecule phase diagram showing the transition phases between solid, liquid and gas as a function of temperature and pressure

-

- Molar mass 94.939 g/mol

- Content in dry air /

-

Critical Point

- Temperature 190.85 °C

- Pressure 69.29 bar

- Density 624.60 kg/m³

-

Triple Point

- Temperature -93.71 °C

- Pressure 2.07E-3 bar

Pressure 1.013 bar

| Latent heat of fusion (at melting point) | 62.977 kJ/kg |

| Melting point | - 93.71 °C |

Pressure 1.013 bar

| Boiling point | 3.51 °C |

| Latent heat of vaporization (at boiling point) | 253.396 kJ/kg |

| Liquid density (at boiling point) | 1721.37 kg/m3 |

Applications

Examples of uses of this molecule in Industry and Healthcare

Chemicals

Methyl bromide is used as a methylating agent in various chemical reactions and as a solvent.

Other

Methyl bromide is used to control fungi, insects and rodents.

Safety & Compatibility

GHS04

Gas under pressure

GHS06

Acute Toxicity

GHS08

Serious health hazard

GHS09

Hazardous to the environment

Autoignition Temperature, Flammability Limits & Flash Point

Europe (according to EN1839 for Limits and EN 14522 for autoignition temperature)

| Autoignition temperature (Chemsafe) | 535 °C |

| Lower flammability limit (IEC 80079-20-1) | 8.6 vol% |

| Upper flammability limit (IEC 80079-20-1) | 20 vol% |

US (according to ASTM E681 for Limits and ASTM E659 for autoignition temperature)

| Autoignition temperature (NFPA 325) | 537 °C |

| Flash point (NPFA 325) | Practically nonflammable |

| Lower flammability limit (NFPA 325) | 10 vol% |

| Upper flammability limit (NFPA 325) | 16 vol% |

Threshold of toxicity

| PEL USA OSHA (vol) | 20 [ceiling] ppm |

Odor

Chloroform like

Metals

| Aluminium | Not recommended |

| Brass | Satisfactory |

| Monel | Satisfactory |

| Copper | No data |

| Ferritic Steel | Satisfactory |

| Stainless steel | Satisfactory |

| Zinc | No data |

| Titanium | No data |

Plastics

| Polytetrafluoroethylene | Satisfactory |

| Polychlorotrifluoroethylene | Satisfactory |

| Polyvinylidene fluoride | Satisfactory |

| Polyvinyl chloride |

Significant swelling

Not recommended

|

| Ethylene tetrafluoroethylene | No data |

| Polycarbonate |

Significant swelling

Not recommended

|

| Polyamide | Satisfactory |

| Polypropylene |

Significant swelling

Not recommended

|

Elastomers

| Butyl (isobutene- isoprene) rubber |

significant swelling

Not recommended

|

| Nitrile rubber |

significant swelling

Not recommended

|

| Chloroprene |

significant swelling

Not recommended

|

| Chlorofluorocarbons | No data |

| Silicone |

significant swelling

Not recommended

|

| Perfluoroelastomers | Satisfactory |

| Fluoroelastomers | Satisfactory |

| Neoprene | No data |

| Polyurethane |

Significant swelling

Not recommended

|

| Ethylene-Propylene |

Significant swelling

Not recommended

|

Lubricants

| Hydrocarbon based lubricant |

Significant loss of mass

Not recommended

|

| Fluorocarbon based lubricant |

Significant loss of mass

Not recommended

|

Materials compatibility

Learn More

More information

Due to their ozone-depleting effect, the production of refrigerants is continuously decreasing, based on Montreal protocol requirements. Their use is controlled and they are progressively being replaced.