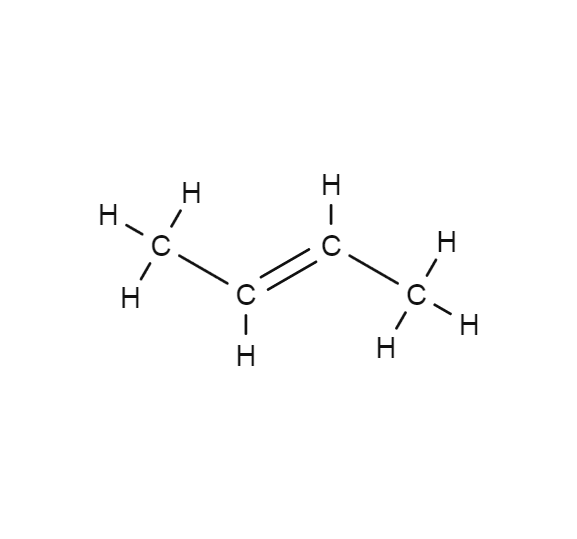

2-trans-Butene

- C4H8

- CAS Number 624-64-6

- UN1012 (gas)

Click & drag to move the 3D molecule

Liquid / Gas Volumes

Calculate the volume or mass of a quantity of gas or liquid

Liquid Phase

At boiling point at 1.013 bar

Gas Phase

In standard conditions (1.013 bar, 15°C)

Physical Properties

Molecule phase diagram showing the transition phases between solid, liquid and gas as a function of temperature and pressure

-

- Molar mass 56.106 g/mol

- Content in dry air /

-

Critical Point

- Temperature 155.45 °C

- Pressure 41 bar

- Density 235.74 kg/m³

-

Triple Point

- Temperature -105.55 °C

- Pressure 7.45E-4 bar

Pressure 1.013 bar

| Latent heat of fusion (at melting point) | 173.913 kJ/kg |

| Melting point | - 105.53 °C |

Pressure 1.013 bar

| Boiling point | 0.88 °C |

| Latent heat of vaporization (at boiling point) | 405.19 kJ/kg |

| Liquid density (at boiling point) | 626.45 kg/m3 |

| Gas density (at boiling point) | 2.605 kg/m3 |

| Specific gravity | 1.93 |

| Vapor pressure | 9.814E-1 bar |

| Compressibility factor Z | 9.651E-1 |

| Cp/Cv ratio γ | 1.1268 |

| Gas density | 2.4587 kg/m3 |

| Heat capacity Cp | 1.5845 kJ/(kg.K) |

| Heat capacity Cv | 1.4062 kJ/(kg.K) |

| Specific gravity | 1.93 |

| Specific volume | 4.068E-1 m3/kg |

| Thermal conductivity | 16.135 mW/(m.K) |

| Vapor pressure | 1.688 bar |

| Viscosity | 7.7419E-5 Po |

| Compressibility factor Z | 9.693E-1 |

| Cp/Cv ratio γ | 1.1209 |

| Gas density | 2.3659 kg/m3 |

| Heat capacity Cp | 1.6105 kJ/(kg.K) |

| Heat capacity Cv | 1.4367 kJ/(kg.K) |

| Specific gravity | 1.93 |

| Specific volume | 4.228E-1 m3/kg |

| Thermal conductivity | 17.106 mW/(m.K) |

| Vapor pressure | 2.3428 bar |

| Viscosity | 8.028E-5 Po |

Applications

Examples of uses of this molecule in Industry and Healthcare

Chemicals

2-Butenes have end uses in the production of butyl rubber. They are also used as feedstock for the production of propylene or mixed octenes.

Safety & Compatibility

GHS02

Flammable

GHS04

Gas under pressure

Autoignition Temperature, Flammability Limits & Flash Point

Europe (according to EN1839 for Limits and EN 14522 for autoignition temperature)

| Autoignition temperature (Chemsafe) | 324 °C |

| Lower flammability limit (IEC 80079-20-1) | 1.6 vol% |

| Upper flammability limit (IEC 80079-20-1) | 10 vol% |

US (according to ASTM E681 for Limits and ASTM E659 for autoignition temperature)

| Autoignition temperature (NFPA 325) | 324 °C |

| Lower flammability limit (NFPA 325) | 1.8 vol% |

| Upper flammability limit (NFPA 325) | 9.7 vol% |

Metals

| Aluminium | Satisfactory |

| Brass | Satisfactory |

| Monel | No data |

| Copper | No data |

| Ferritic Steel | Satisfactory |

| Stainless steel | Satisfactory |

| Zinc | No data |

| Titanium | No data |

Plastics

| Polytetrafluoroethylene | Satisfactory |

| Polychlorotrifluoroethylene | Satisfactory |

| Polyvinylidene fluoride | Satisfactory |

| Polyvinyl chloride |

Significant swelling, change of mechanical properties

Not recommended

|

| Ethylene tetrafluoroethylene | No data |

| Polycarbonate | No data |

| Polyamide | Satisfactory |

| Polypropylene | Satisfactory |

Elastomers

| Butyl (isobutene- isoprene) rubber |

Significant swelling and modification of the properties of the material

Not recommended

|

| Nitrile rubber | Satisfactory |

| Chloroprene |

Significant swelling

Not recommended

|

| Chlorofluorocarbons | No data |

| Silicone |

significant swelling and modification of the properties of the material

Not recommended

|

| Perfluoroelastomers | Satisfactory |

| Fluoroelastomers | Satisfactory |

| Neoprene | No data |

| Polyurethane |

Significant swelling, change of mechanical properties

Not recommended

|

| Ethylene-Propylene |

Significant swelling and modification of the properties of the material

Not recommended

|

Lubricants

| Hydrocarbon based lubricant |

Significant loss of mass

Not recommended

|

| Fluorocarbon based lubricant | Satisfactory |